Switchblades are a real joy to use. They are quick and efficient but more than that they’re just outright cool. The feeling of flicking a switch, and having a blade spring out and click into place is so satisfying. Maybe it even gives you a small feeling of power.

Switchblades are not readily available and in some parts of the world, they’re illegal. Despite this, there is another way to get a switchblade knife and that’s to make it yourself but what do you do if you have no idea how to make a knife?

Well, we’ve got news for you! We’ve come up with five easy steps on how to make a switchblade. Homemade versions of anything are not as good as the original but they will function in many of the same ways. So don’t turn away just yet have a look at our tips and see for yourself. Here’s our guide to making your own switchblade.

1. How A Switchblade Works

This particular type of knife is quite simple. It has a switch on the handle that opens the blade when pressed. It sounds simple and is easy to operate but it’s a whole lot more complicated to make on your own. The system, when activated, triggers the spring to open the blade.

Switchblades can operate via a button or a switch and both function in similar ways. Some people prefer a button to push and others a sliding switch. The tang of the knife has a spring-loaded between a small groove carved into it and a piece of steel called a stopper. When the blade is closed it compresses the spring making it ready for when the switch is triggered.

Upon pressing the switch or button, the spring is released and pushes the knife open. Some switchblades operate on a partial opening mechanism and others on a full open mechanism.

One allows immediate use of the knife once opened while the other has to be opened the rest of the way manually. Partial mechanisms are designed to prevent the blade from opening if the button is pushed or bumped accidentally.

2. Materials

Not much is needed to make a switchblade. All you need to start is a material for the handle either wood or a form of hard material like fibreglass for instance. Additionally, you will need screws or pivots to hold the knife together.

The mechanism will be comprised of a spring and a stopper so you’ll need to find those as well. If you’re going to use wood for the handle then you’ll need to take more care when shaping and preparing the handle. One way to ease the process of knife making is to find great quality wood.

You’ll need to ensure that the screws or pivot pins that you source are strong and rust-resistant. In fact, all the metallic components need to be made of stainless steel for promised utility and long life.

3. Safety

During the process of making a switchblade, you’ll be using machinery and electrical tools. These machines can be dangerous so a lot of care must be taken. Use of personal protective gear such as gloves, face masks, or face shields is a must.

When shaping the knife blade you’ll need to use an electric metal lathe. This machine runs at high speeds and so great caution must be taken to avoid serious injury. It’s dangerous and we would recommend consulting a professional to help you unless you are fully confident in your ability. The same goes for when you’re shaping the handle pieces or machining any screws.

When working on the mechanism of the switchblade we recommend using an unsharpened blade edge. Sharpening should be the last thing that you do when making a homemade switchblade. This is because the spring could cause a loss of control when handling the blade which could lead to injury.

4. Switchblade Design

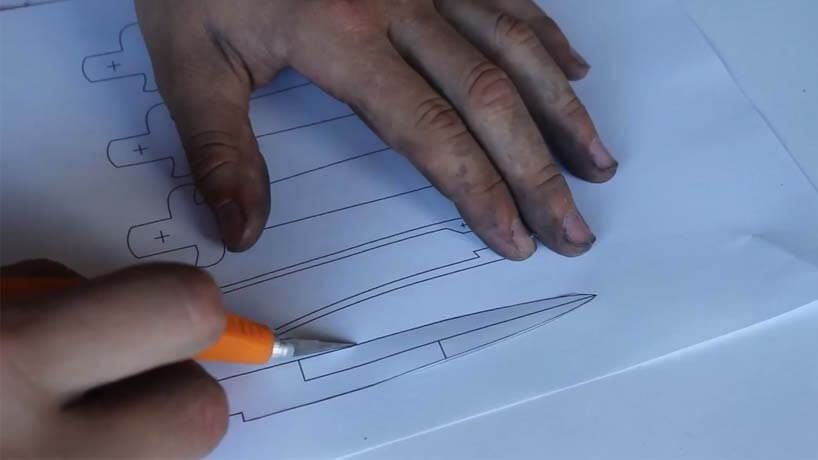

You can never start anything until you have a plan in place. So we’d recommend you put together a simple design with dimensions that you can refer to when buying the necessary parts. We recommend making your dimensions as accurate as possible. It may be a DIY switchblade but if you want it to be a success then you need to make this a priority.

If your design is not accurate then as you start to assemble the pieces you’ll notice misalignments. Meaning that your knife is not going to function properly. This is a catastrophic failure and will mean having to start again from scratch.

So draft together some blueprints in order to know the exact sizes and shapes you’re going for. You’ll need to know the size of spring that you’ll need as well as the stopper size too. These pieces need to fit together cleanly.

The spring needs to fit into the allotted space while still being strong enough to flick the blade open. The stopper needs to be made of strong material to be able to withstand excessive forces while being used.

5. Blueprint Switchblade Knife Mechanism

The mechanism we’ll describe is the simplest for at-home methods. The first step is to shape the handle pieces in the prescribed way that you designed. This will be done on a lathe. When shaping the blade you’re going to leave the tang in a circular shape. You can shape the blade edges however you’d like, just make sure that there is enough room to close the blade into the handle nicely.

The circular tang will help you with the spring mechanism. Now place the blade into the handle with the sharp side pointing down. Flip the knife upside down and make a mark on the tang where it sticks out slightly. This will be where we make our groove for the stopper placement. Shape a groove onto the tang in this area.

The piece of steel that’ll be used as the stopper will be connected to the handle. This will need to be connected before the handles are assembled and before the blade is screwed on. The stopper needs to rest against the switch button. This is so that when the switch is activated it’ll be able to get pushed out the way and this will allow the spring to uncoil. After everything is assembled make sure it’s all working smoothly with no glitches or safety concerns that come to your attention.

Conclusion

Making a switchblade is more complicated than one might think so you need to take your time. If you rush into the design without taking the necessary precautions then the knife won’t work right.

Use accurate measurements and have a solid idea of how you want the switchblade to function. Spend copious amounts of time with the design until you’re confident that the knife will operate perfectly. Then proceed to develop the pieces of the puzzle. Get in contact with professionals and do extra research for yourself to further your ability to conjure up a beautiful switchblade.